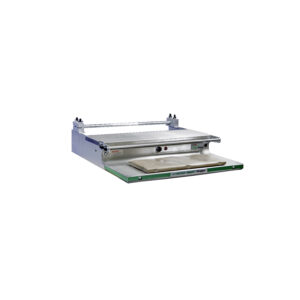

Wondering how to clean your Heat Seal food packaging machine? Here are 5 tips drawn from ALFA’s 77 years of experience to maintain your Heat Seal food wrapper..

Heat Seal’s food wrapping machines have set the industry standard for 65+ years.We believe in the quality of the product, which is why ALFA International Dealers have been selling Heat Seal products for 2+ decades. Heat Seal’s machines are engineered to withstand intense use day-in-day-out. And they do. But that doesn’t mean you don’t have to maintain them along the way.

Here are 5 maintenance tips that the ALFA team wants you to know….Before we begin,ALFA’s Legal staff wants us to remind you: BEFORE CLEANING, TURN OFF & UNPLUG your Heat Seal Machine. Allow your machine to cool down PRIOR to cleaning to protect yourself and your equipment.

#1 “Wear Parts” on Heat Seal Machines Are EASY to Replace

If you don’t have to, don’t replace that machine! Save money by replacing the worn components.The most commonly replaced components include:

- Heat Seal Teflon Seal Plate Cover: ALFA part HS5901, HS5902, HS5903, or HS5905

- Heat Seal Heating Element: ALFA part HS6110 or HS6504

- Heat Seal Cut Off Bar/ “Hot Rod”: ALFA part HS1824

- Heat Seal Thermostat: ALFA part HS1881

- Heat Seal Circuit Board: ALFA part HS1818

#2 Replace the Non-Stick Cover at Least Every 3 Months

It is extremely important to maintain the non-stick cover or seal plate protective cover in good condition. Doing so maintains a safe, sanitary surface and prevents wear on the seal plate underneath. Look out for worn corners, tears or discoloration of the Teflon cover, which are common signs of wear, and replace the cover accordingly.AT MINIMUM, THE NON-STICK COVER SHOULD BE REPLACED EVERY 3 MONTHS ,but it depends on how heavily the Heat Seal Unit is used. Some of ALFA’s high volume chain customers must change it every 2 weeks!

#3 Never Use the Seal Plate as a cutting surface

This is a simple rule,but one that is often violated. Put simply: SEAL PLATE PUNCTURES/CUTS VOID YOUR WARRANTY & RENDER YOUR SEAL PLATE INEFFECTIVE.

#4 Clean the Seal Plate

The Non-stick cover on Heat Seal machines is porous. Liquids or moisture can flow through the cover to the surface of the seal plate, where they will burn on the hot plate itself. You can do two things to:

1)Replace the non-stick cover–at least every 3 months-if the surface is soiled, or holes, punctures, excessive wear or damage are present, the non-stick cover must be replaced!

2)Clean the seal plate with a disinfectant or Stainless Steel cleaner. For guidance choosing a Stainless Steel cleaner, read our past post:How to Clean Stainless Steel Restaurant Equipment

#5 Frequently Clean the Cut Off Rod

Over time, the cut off, or “hot rod” collects a build up of wrapping film and food residue. This build-up can eventually prevent the cut off rod from working. We’ve found that cleaning this component can greatly extend its life.

Here are step-by-step instructions to do that.Heat Seal also has a great YouTube video that details the process:Heat Seal Maintenance Video

- Step 1: Before cleaning: MAKE SURE UNIT IS TURNED OFF AND CUT OFF ROAD IS COLD TO THE TOUCH!!

- Step 2: Cover the base of the unit with paper towels to protect it from the degreasing spray and debris.

- Step 3: Spray and coat the cut off road with an FDA approved degreasing product

- Step 4: Let the rod soak for a few minutes.

- Step 5: Lightly scrub the surface with a scour pad to remove film

- Step 6:Wipe the surface clean of residue.

- Step 7: If the rod is still not clean repeat steps 3-6.